MPS reports a rewarding five-day Open House during drupa

MPS opened its doors at its headquarters in Arnhem, The Netherlands during drupa 2016 between June 1-7, and has reported a rewarding, well-attended event. Open House visitors were treated to live demonstrations on the MPS EF multi-substrate, EB label solution and the hybrid flexo/digital EF SYMJET presses, and a factory tour that included an impressive 28-metre long offset combination press: the largest ever built by the company.

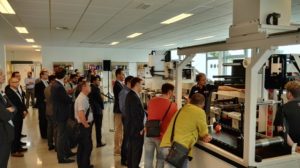

During the five-day Open House, MPS received over 150 visitors representing 24 different nationalities. Aakon Schüssel, sales and marketing director of MPS, said: “We are pleased to have had the opportunity to welcome so many visitors from all over the world, who took time during drupa to visit our Technology & Expertise Centre in Arnhem. This Open House surpassed all our expectations.”

A private ‘MPS Express’ bus took drupa visitors to Arnhem where they were welcomed at the Technology & Expertise Centre. After an opening greeting delivered by Schüssel, MPS print manager Hans Poortinga kicked off the live demonstrations with a presentation of advanced workflow integration and efficiency benefits between the Label Traxx MIS/ERP module and AVT 100 per cent inspection system. The first press demonstration was the EF multi-substrate press, on which a 3-ply multi-layer label was printed. This complicated job was demonstrated in perfect register with speed reaching 120 m/min.

Demonstrated next was the EB label solution press, running a job of self-adhesive labels with print on the glue side on 360mm print width material, using delam-relam. Shown were the differences and similarities between the two presses, as the identical image was printed.

MPS operators quickly changed the substrate on the EF press to a thin 40 micron BOPP mono film, to prove its capability to print on any substrate, before the demonstration of the foil job on the EF continued. Lastly, a live demonstration was given on the new hybrid EF SYMJET press, which MPS recently launched into the narrow web label market. Poortinga demonstrated the advantages of hybrid flexo/digital printing by running a self-adhesive label with cold foil application, and a variation in colour, using the integrated digital Domino N610i unit.

The Open House program was completed with a factory tour. A memorable moment during the five-day event was the on-site signing of a new MPS flexo press order with a Polish customer.