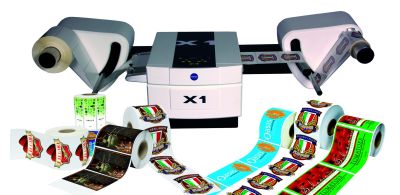

X1 and LF3 make ideal package

Impression Technology Europe have put together a package of printer and finisher that will satisfy the demands of both the established printer looking for extra output and businesses looking for a cost-effective entry package. The combination of the Rapid X1 and the Compress Eclipse LF3 gives the user the ability to print and convert standard continuous blank stock into high quality, full colour labels fully cut and slit ready for application. Although promoted as a package each part is available in its own right and represents the highest quality in its class.

The Compress LF3 is the new part of the package. Although it has only been recently introduced to the industry it has already made a name for itself with machines being delivered to major markets around the world including Australia, India, Europe, USA and, of course, the UK. Designed and developed totally in the UK by Impression Technology Europe, the LF3 is a compact unit that handles intricate cuts and trims as well as full slitting giving a finished label ready to apply. So nothing new there you may say but the specification goes much further than that. This machine also handles lamination which comes as a standard part of this model. Compact and self-contained would be a good description for this impressive piece of kit as, coming in at 1000m x 600mm x 780mm, the Eclipse LF3 does not demand a lot of space. It boasts a maximum label length of 305mm with a cut width of 100mm to 220mm and can handle a roll size up to 300mm (with a maximum core size of 76mm). It uses single point registration for cutting and has full waste matrix removal and rewind. The packaged software, WINPLOT, utilises Windows operating systems and has plug-ins for both CorelDraw and Adobe Illustrator. Although it can handle unprinted media it really comes into its own when teamed up with the Rapid X1 to produce fully finished high quality printed stock.

The Rapid X1 is the established part of the package having been well established in the market for quite a while now. This table top unit utilises Memjet print head technology to produce very high quality printed labels at an amazing speed. The in-line print head does not move, as with other printers, but instead uses 72,400 nozzles to deliver 744,000,000 droplets of ink per second allowing delivery of labels at a print speed of, up to, 18m per minute. This amazing little machine has an ‘unwind and rewind’ system and even comes with optical sensors for pre-cut labels. Using a five colour system (CMYK+K) the print quality is stunning with sharp images and vibrant colours. Best of all though is the fact that, as this is a digital printer running from a standard Windows PC, each label can be individual so whether you are working on a long or short run, the cost to you is the same even if, for instance, you give each label an individual mark or tracking number. This opens up the lucrative small order market to label printing that isn’t constrained by higher set-up costs normally associated with small runs. It also makes it the ideal unit for production specialist labels to enhance stock control or logistical tracking.

Not only is the Rapid X1 easy to use but the developers have even factored maintenance into the equation with the print head being user-changeable thus avoiding expensive call out charges.

With both machines offering a cost effective solution each, on its own merit, stands as an individual piece of production equipment that will fit into any environment whether that is an established printer or a start-up business. Put them together though and they take on a whole new character and represent high production without the buyer having to commit lots of space. The small footprint of both models makes them an easy addition to any plant but especially to those where space is at a premium.

For more information about ITE or the products they supply or to find your nearest distributor call them on +44 1623 861173 or e-mail them at info@impressiontechnologyeurope.com. You can link to the Rapid web site and the DTG one by visiting www.impressiontechnologyeurope.com